SWR Ring Fit Pipe Fittings

- Non Corrosive

- Resistance To chemical

- Thogh & Reliable

- Easy Cold Welding Process

- Prevent Bacterial Growth

- Low Thermal Expansion

- life of More than 50 Years

- For Sewage Waste & Rain Water

SWR RINGFIT PIPES AS PER IS: 13592, SWR RINGFIT FITTINGS AS PER IS: 14735

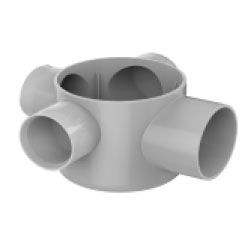

Fittings

Standard & Specification

PROPERTIES OF SWR RING FIT PIPE :

Vigor SWR (Soil, Waste, and Rainwater) Ring Fit Pipes are designed for use in drainage systems in buildings. These pipes typically possess several beneficial properties that make them suitable for such applications. Here are some general properties associated with Vigor SWR Ring Fit Pipes:

High-Quality uPVC Material:

Vigor SWR Ring Fit Pipes are commonly made from high-quality unplasticized polyvinyl chloride (uPVC), ensuring durability, longevity, and resistance to corrosion.

Corrosion Resistance:

These pipes offer excellent resistance to corrosion from chemicals, acids, and alkalis commonly found in sewage and drainage systems, ensuring long-term reliability.

Chemical Resistance:

They resist a wide range of chemicals, making them suitable for use in environments where exposure to corrosive substances is common, such as industrial settings and wastewater treatment plants.

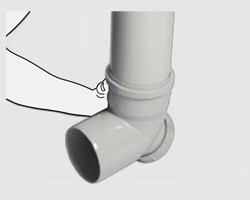

Leak-Proof Joints:

Vigor SWR Ring Fit Pipes are designed with ring-fit joints, ensuring tight and leak-proof connections between pipes, preventing the escape of wastewater or gases.

Easy Installation:

These pipes are designed for easy and efficient installation, allowing for quick assembly and reducing labor costs during construction or renovation projects.

Compatibility:

Vigor SWR Ring Fit Pipes are typically compatible with other SWR fittings and accessories, providing flexibility in system design and installation.

Temperature Resistance:

They exhibit high temperature resistance, allowing for use in applications where elevated temperatures may be encountered, such as hot water drainage systems.

Dimensional Accuracy:

Vigor SWR Ring Fit Pipes are manufactured to precise dimensional tolerances, ensuring proper fitment and alignment within the drainage system.

Note: Vigor CPVC pipes means unplasticised polyinylchloride pipe, also frequently referred to as rigid PVC pipe. The word rigid does not explain its structure, but denes a property, which is self explanatory.

Installation Guide

Easy and 100% leakproof installation.

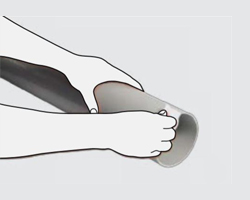

Step 1: Cutting

Measure and cut pipe to size. Ensure to cut the pipes straight and square. Inspect pipe ends thoroughly before making the cut, if any cracks or split in the ring is noticed cut off a minimum of 25 mm beyond the visible crack before proceeding..

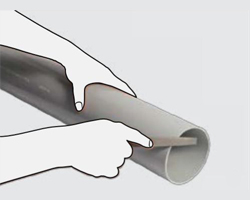

Step 2: Chamfering and Deburring

Burrs in and on pipe end can obstruct flow/proper contact between the pipe and socket of the fitting during assembly and should be removed from both in and outside of the pipe. A 15 mm dia half round file/a pen knife or a Deburring tool are suitable for this purpose.

Burrs in and on pipe end can obstruct flow/proper contact between the pipe and socket of the fitting during assembly and should be removed from both in and outside of the pipe. A 15 mm dia half round file/a pen knife or a Deburring tool are suitable for this purpose.

Step 4: Fitting Preparation

Use a clean dry cloth to wipe the dirt, moisture from the fitting and pipe end.

Step 5: Check for Blue Seal™

Check the socket end for Blue Seal™. Ensure that the Blue part of the seal is towards the outside of socket.

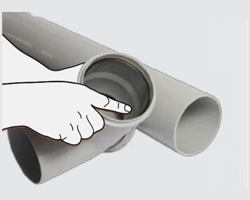

Step 5:: Lubricant

Apply the lubricant on the chamfered end of the pipe.

Step 5: Assembly

Immediately insert the pipe into the fitting socket. Rotate the pipe slightly while inserting. Withdraw pipe until the mark is 12 mm away from socket. This means a 12 mm gap exists between the end of the pipe and the socket register. This gap will allow the pipe to expand without distorting the pipe-work jointing.